Box Strength

Edge Crush Test (ECT) or Bursting Strength Test (Mullen)

Using the correct strength boxes for shipping not only could result in reducing the risk of damage but it could also affect the cost while helping the environment. The older system of testing the strength of corrugated boxes, Mullen Test, measured the amount of force necessary to puncture, burst, corrugated sheets. The Mullen system was invented in 1887 and measures the strength as a pound per square inch, for example, 200# Mullen test box means it takes 200 pounds per square inch to burst the paperboard. This system is not very reliable when measuring the 2 ply (double walled) corrugated sheets.

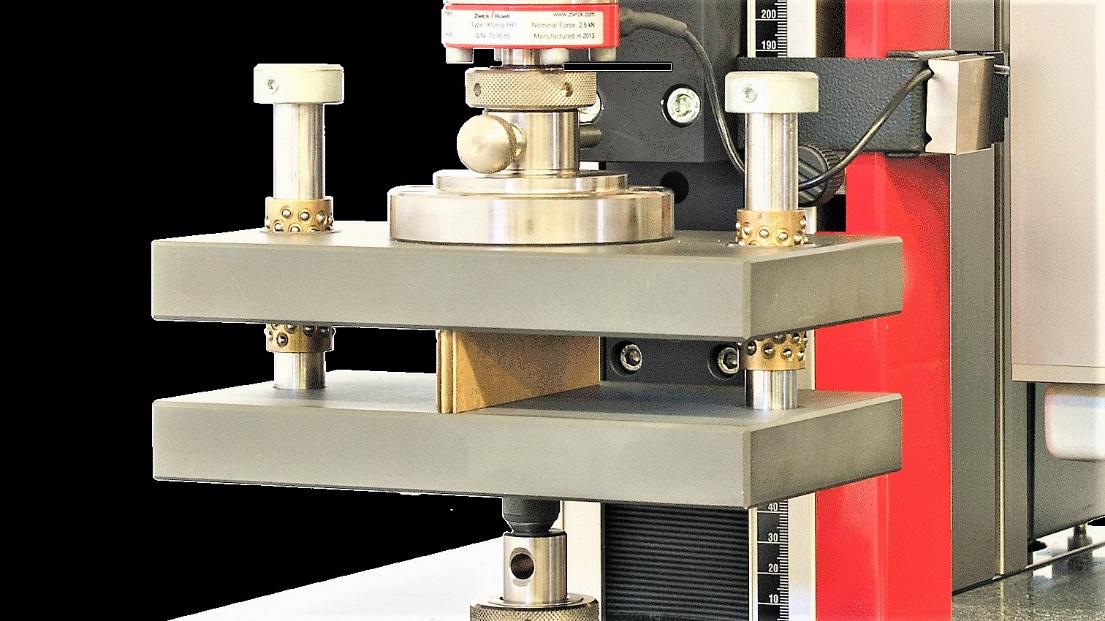

The ECT, Edge Crush Test, is a newer method of testing the strength of the boxes instead of the cardboard sheets. Many consider the ECT a more accurate test because it measures the integrity of the boxes under pressure along with their stackability. The ECT concentrate on how much force will crush a box with the corrugated flutes on a vertical position. This is important because the vertical flutes are the reason for the additional strength of the corrugated boxes. The thickness of the cardboards alone cannot create the strength offered, however, corrugated sheets with the flutes hold the strength. The addition of these flutes placed in vertical position creates an extra resistance against crush while the boxes are stacked.

The use of corrugated cardboard sheets has made the ECT a better standard while measuring the box strength instead of the sheets. The corrugated sheets in today’s moving boxes are made of fluted cardboard sheets glued to the flat sheets creating much stronger sheets. The corrugated sheets are then folded to create packing boxes in different sizes.

|

Weight |

Mullen # Per Square Inch |

Edge Crush Test (ECT) |

|

20 Lbs. |

125# |

23 ECT |

|

35 Lbs. |

150# |

26 ECT |

|

50 Lbs. |

175# |

29 ECT |

|

65 Lbs. |

200# |

32 ECT (Most Common) |

|

80 Lbs. |

225# |

40 ECT |

|

90 Lbs. |

300# |

44 ECT |

|

120 Lbs. |

326# |

55 ECT |

The numbers in the above chart do not exactly relate from one method to the other. For example, a 200# Mullen tested box could fall between 32 ECT to 44 ECT. This is due to the Edge Crush Test represents the “minimum” amount of the force necessary to crush the corrugated sheets. Each manufacturer employs a different process in gluing the cardboard pieces together. The difference in the process may result in one product being stronger than others with the minimum amount of the pressure, measured as a pound per square inch, will be the same for all.

The main difference between the two methods for the consumer remains in the cost-effectiveness of the ECT boxes. A 1,000 square feet of the cardboard used in 44 ECT single wall box could weigh 149 LBS. while the similar 275# Burst Tested single wall weighs 175 Lbs. This makes the ECT rated corrugated sheets 26 pounds or near 15% lighter than the 275# Mullen tested.

The ECT rated boxes offer lighter weight to do the same job as Burst tested boxes but costs less, uses fewer materials resulting in less pollution and landfill while the less weight saves fuel during the transport.