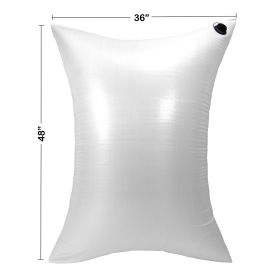

5 Dunnage Bags 36" x 48" Freight Saver With Free Flow Inflator/Deflator Gun

- 5 sturdy StarBoxes Dunnage Bags 36"x48" Poly Woven

- FREE Flo-Inflator - Inflator/Deflator takes seconds to fill a Polywoven dunnage bag

- Inflator tool has ease of use with time-saving deflator mechanism

- Freight Stabilizer bags are used on railways, ocean freight, Trucks, and containers

- Economical air-filled bags are reusable, waterproof, and recyclable

Dunnage Bags for Load Stabilization

Shifting of loads during transit plays a significant role in increasing the damages to cargo as well as the road accidents associated with the trucking industry. The solution is very simple but often neglected. Dunnage Bags are inflatable Cushioning Bags designed to fill the void in the containers to reduce or stop the shifting of the contents. The Dunnage Air Bags 36"x36" offer a superb ability as load stabilizers along with the low cost and easy to use functionality.

Pros and Cons of Using Dunnage Bags

The StarBoxes Dunnage Bags are 100% leak-proof Air Cushions offering a high-quality inflatable load stabilizing system at a fraction of cost. There are many advantages to the use of Dunnage Bags:

Pros:

- Protection of Cargo – The inflatable Dunnage Bags protect cargo from damages associated with the shift of the cargo during shipping by securely occupying the void area and leaving no space for the shift to happen. Dunnage Bags protects Shipping Boxes, pallets, and other forms of cargo from moving during transportation. The protection against the shift of the cargo is the ultimate solution in reducing damages to the contents while lowers the risk of traffic accidents

- Cost-Effective – The Dunnage Bags are among the most economical and effective load bracing tools in the market. StarBoxes offers a great selection of sturdy Dunnage Bags at the most competitive prices direct to businesses

- Dunnage Bags are Reusable – The Dunnage Bags by StarBoxes are manufactured from heavy-duty materials to offer many uses out of these rigid Air Cushions. The bags deflate flatly in a very short time. The airless, flatten bags require minimal storage space creating easy storage till their next use. Please note that not every Dunnage Bags in the market are reusable. This is especially true with Kraft Paper Dunnage Bags, which are a form of one-time use, Disposable Dunnage Bags

- Ease of Use – StarBoxes’ Dunnage Air Bags are very easy to use and require little to no staff training. The ease of use of the Dunnage Bags also reduces the loading work-hours resulting in the reduction of labor costs.

- Quick and Easy Inflation and Deflation – The inflating or deflating of StarBoxes’ Dunnage Bags is fast and effortless. This will also help in reducing the labor-hours necessary for securely loading the containers resulting in lower labor costs

Cons:

- Damages to Dunnage Bags – Dunnage Bags like most inflatable devices are prone to puncture when exposed to sharp objects. As a precautionary check the loading area for any object that may puncture the air-filled bags. If the Dunnage Bags become damaged and unusable, they are 100% recyclable.

Use of Dunnage Bags for Securely Loading Containers and Trucks

Following a few precautionary steps will ensure the correct loading of containers and trucks and maximizing the role of Dunnage Bags in securely bracing the cargo. This will also help in reducing the damages to the reusable Dunnage Air Bags:

- Remove Sharp Objects – Remove any sharp objects or nails in the trailer or other cargo containers. Sweep the floor of containers and inspect all areas which will come in contact with the Inflatable Dunnage Bags to clear the surface from any objects which may puncture the Airbags.

- Tight Load – Load the skids very close and touching each other. The tight loading of cargo offer less chance for skids to shift.

- Balancing the Load – The load in the container could be easily balanced by simply alternating the void from one side to other

- Loading Fragile Cargo – All fragile, as well as the tallest cargo, should be loaded first toward the nose of the container.

- Using Dunnage Bags – First load the front of the containers tightly, put a deflated Dunnage Bag on each side of the load, and inflating them making sure there is no void space left for cargo to move. If cargo is not well stabilized, use additional Inflatable Dunnage Bags to completely fill the void and stop any shifting of the skids

- Inflating the Dunnage Airbags – Place the deflated Dunnage Air Cushions on the sides of the skids and inflate them by using the StarBoxes’ Dunnage Bags Inflator

- Protecting the Dunnage Bags from Damages – It is recommended to place corrugated boards between the Dunnage Air Bags and cargo, pallets, or the walls of the containers to avoid puncturing the Airbags

- Finish Loading with Dunnage Bags – Most of the cargo damages happens in the front section or the last 15’ of the loading area of the container. Securing this section, immediately next to the back doors in the trailers, with Dunnage Air Bags will eliminate the risk of damages

| SKU | DUNNAGE36485 |

|---|---|

| UPC | 810042155077 |

| Brand | UOFFICE |

| Manufacturer | uBoxes LLC |

| Color | White |

| Material | Polywoven Polypropylene / LDPE |

| Features / Information | Polywoven material, Reusable, Recyclable, Waterproof, Walk away deflate, Lightweight, AAR approved, Use a free flow inflator/deflator gun |

| Country of Manufacture | United States |

| Weight | 4.000000 |

| Product Length | 48.000000 |

| Product Width | 36.000000 |

| Product Height | 0.000000 |

| • | Sturdy Freight Bags that have been AAR Certified and inflate in less than a minute |

| • | Reduce expenses with freight mishaps when loading trailers or containers properly |

| • | Easy to use with one hand inserting the bag while using the other hand to inflate the dunnage bags |

| • | The patented gun will fill the freight bag to just the right amount of air and then release air out the back of the gun when filled |

| • | High burst stength and chemically resistant enable for these bags to be used in most shipments |