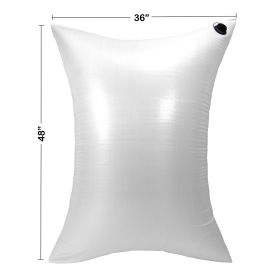

Dunnage Bag 36" x 36"

- Order by the singles StarBoxes 36"x36" Freight Saver Air Filled Dunnage Bags

- Lightweight and reusable make these air-filled poly woven bags an effective cost-saving tool

- Easy to store when deflated with a patented free-flo inflation/deflation system

- Increases cube efficiency and protects the product while being transported

- Free-flo inflation gun sold separately or in a dunnage bag kit

- Buy 10 for $6.25 each and save 57%

- Buy 20 for $5.88 each and save 60%

- Buy 30 for $5.46 each and save 63%

How to Use Dunnage Bags

Dunnage Bags are by far the most effective and economical cargo protection solution currently available on the market. Although using the Dunnage Bags is simple and there is no need for skilled labor and intensive training there are few important steps in making the use of the Dunnage Bags more effective.

Dunnage Air Cushions are used in trucking industries as well as the railroad cars and ocean vessels as a cargo bracing tool for eliminating the shift of the cargo during transit. The correct installation of the Dunnage Bags is essential in protecting the pallets, Shipping Boxes, or other cargo from damages suffered due to their movements. Any increase in the amount of damaged cargo will result in more financial loss than the mere cost of the goods. Returning the damaged goods will increase the shipping costs while the repacking requires labor hours which otherwise would not be necessary.

Costs of Damages Due to Improper Usage of Dunnage Bags

- Cost of Replacement – The damaged goods have no use for your customers and the replacement means an increase in costs. This could have been easily avoided if the Dunnage Bags were installed correctly.

- Canceled Orders – Some customers may cancel their orders after receiving the damaged products. This could be due to the timing for seasonal items or they found another source after repeatedly receiving damaged goods which either were not protected with Dunnage Bags or the Dunnage Bags were installed incorrectly.

- Goodwill and Reputation of Company – Any business person knows there is no price for the goodwill and stellar reputation of their company. An increase in the delivery of damaged products will eventually result in tarnishing their good company name.

- Increase in Labor Costs – The receiving, assessment, repacking and reshipment or disposal of the returned products have a direct impact on the labor costs.

- Increased Customer Service Complaints – The calls and complaints by customers who have received the damaged products mean additional work hours for the customer service department and accounting departments.

Dunnage Bag Protection

The above examples are some of the points emphasizing the importance of the Dunnage Airbags in bracing and protecting cargo while in transit. The following easy steps are instrumental in the complete utilization of the protection offered by Dunnage Bags:

- Loading the Container – First, load the first row tightly in the container where the void area is clearly visible and concentrated in one or two areas. Depending on the load, the empty space could be either on each side of the cargo by the container’s walls or in the middle with cargo pushed against the walls.

- Loading with Dunnage Bags – After the void area is recognized, determine the number and size of the Dunnage Bags needed to secure the cargo. The deflated Dunnage Air Cushions are flat and can easily fit into the empty spaces. It is important to remember to place the inflation valve towards outside within the easy reach for inflation.

- Securing Dunnage Bags – StarBoxes Polywoven Dunnage Bags are reusable and protecting them against damages will result in more usage opportunities and a reduction of the costs. Check the container walls as well as the pallets, Shipping Boxes, or other forms of cargo for nails, sharp corners, or any objects which may damage the Dunnage Bags. Inserting a sturdy sheet of corrugated cardboard next to Dunnage Bags will be a great help in reducing the damages to the bags.

- Inflating the Dunnage Bags – Now that the deflated Dunnage Bags are properly placed in the void area it is time to inflate them. Inflate the Dunnage Bags to their full capacity making sure they have occupied the void area with no room for cargo to move. The AAR-certified Dunnage Bags by StarBoxes are equipped with Free-Flow Air Tools for faster and easier inflation without overinflating the dunnage bags.

- Complete Loading with Dunnage Bags 36x36 – After the first row is secured, continue with the same procedure until the last row is loaded. After the last row, make sure all void areas are filled with the Dunnage Airbags and there is no empty space between the doors and the cargo after the doors are closed.

| SKU | DUNNAGE36X36 |

|---|---|

| UPC | 810042156227 |

| Brand | UOFFICE |

| Manufacturer | uBoxes LLC |

| Color | White |

| Material | Polywoven Polypropylene / LDPE |

| Features / Information | Polywoven material, Reusable, Recyclable, Waterproof, Walk away deflate, Lightweight, AAR approved, Use a free flow inflator gun |

| Country of Manufacture | United States |

| Weight | 0.700000 |

| Product Length | 36.000000 |

| Product Width | 36.000000 |

| Product Height | 0.000000 |

| • | The AAR Certification of UOFFICE quality Dunnage Bags offers is a testimony to rigidness of our leak-proof Inflatable Bags |

| • | Stabilize your pallet loads with sturdy dunnage bags for a protective barrier against shifting and damages |

| • | Polywoven material provides a strong outer exterior resistant to water and is reusable |

| • | Do not over inflate when the air is escaping from the back of the gun the bag is complete |

| • | Buy inflatable/deflatable patentend gun separately for time saving labor and ease of use |